-

Mud Cooler

ISC rent Mud Cooler for drilling operations. The complete design, development, and manufacturing is done by ISC engineering team. The state-of-the-art equipment is designed according to the requirements put forwarded by O&G field operators. Our Mud Coolers are currently running at various rigs in the region. Drilling Mud Cooler also known as drilling mud chiller is generally erected in the mud pool to cool down the high temperature mud. The drilling mud cooler is a heat exchanger which transfers the heat of the mud via a cooling medium of water available in the field.

-

Centralized Fire Alarm Monitoring

Turnkey projects on supply, installation and commissioning of Centralized fire monitoring system for wide area and cluster of building and facilities. The system has an efficient and robust user interface that display, tracks and control fire and security system, alarm, fault, CCTV, Access controls, Announcements etc.; also allows remote monitoring through smart phones as well.

-

Flare Gas to Power

Our Generator unit is designed to meet the demands of oil and gas producers looking to leverage wellhead and stranded gas and/or meet EPA regulations with flare mitigation. The unit’s mobility makes it perfect for changing job sites and providing power to remote locations. Provide up to 350kW of prime power |Microgrid-ready for scalable, multi-megawatt applications |Power Demands: prime, continuous, standby, or backup |Fuel Options: natural gas, wellhead gas, stranded gas, liquid propane

-

Flare Gas Recovery (FGR)

ISC together with Pioneer Energy’s innovative, proprietary flare gas capture and processing systems turn raw associated gas and tank battery vapors from a waste into a resource. The FlarecatcherTM extracts valuable Natural Gas Liquids (NGLs) from associated gas right at the well site, using its Deep RefrigerationTM technology to provide the highest capture efficiency in the industry. It conditions the remaining gas to pipeline quality, making it ideal for high efficiency on-site power generation or conversion to CNG or LNG.

-

Tank Vapor Recovery

Captures & processes high BTU gas, including tank battery vapors. Vaporcatcher separates gas into 2 streams: NGLs: Can be trucked to market to provide significant financial return. Residue gas: Methane, ethane & some propane. Can be used as fuel gas on-site or sent to enclosed combustors. Carbon emissions have been reduced by a factor of 4 and C4+ smoky combustion emissions reduced by a factor of 12.

-

Oil & Gas Well Head Compressors

We provide solutions for wellhead compression to meet all wellhead compression and vapor recovery applications. The units come in either gas drive or electric drive configurations. We incorporate the unit with advanced control panel, the LOGIX PLC, monitors all compressor functions, giving users total control and increased production. All units include satellite telemetry. The technology can also be used in Flare Gas Recovery by compressing the flare gas from atmospheric pressure to a pipeline pressure. Some features include: • Maximum Production: Total automation maintains optimal capacity for the well or site. • Unparalleled Utility: Precision flow control in all applications from simple wellhead production to complex vapor recovery and plunger lift systems. • Ultimate Reliability: Every feature combines time tested and proven hardware with sophisticated process controls and engineering.

-

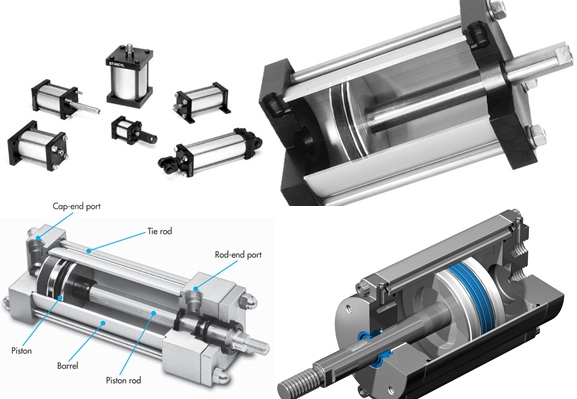

Pneumatic Cylinder Manufacturing

We manufacture double acting Pneumatic cylinder depending on different stroke lengths & cylinder size, standard / custom design available

-

Hydraulic Cylinder Manufacturing

We build, supply new and repair cylinders for Earth Moving, Marine, Press, Crane, Telescopic, Shear, Excavator and Chip Dump applications. We also have the capabilities, experience, and technical knowledge to manufacture new cylinders and custom build cylinders.

-

Hydraulic Hose Crimping Service

Capacity: Crimping service up to 2 inch diameter. Hoses available in 1SN, 2SN, 4SH

-

Hydraulic & Pneumatic Seal Manufacturing

Seal Capacity: Up to 500mm diameter. Seal manufactured in all standard specifications, also available - custom design